Zenner Engineers designs the pneumatic tube system – a sizeable project even by international standards – for the new Oulu University Hospital (OYS). Zenner is the leading designer of large pneumatic tube systems in Finland, and has designed large-scale systems for hospitals since the 1990s.

Pneumatic tube systems were developed already in the 19th century, when growing cities needed a fast and safe way to transport money, documents, or small items from one location to another.

In pneumatic tube systems, deliveries are made with closed carriers with a diameter that is slightly smaller than that of the pipe. In the pipes, the carriers are set in motion by negative or positive pressure, and they can reach speeds of up to 30 km/hour. In hospital use, however, e.g. when transporting samples, slightly lower speeds are generally used to prevent any damage to the samples.

Pneumatic tube systems are built for a wide range of purposes. Large supermarkets use smaller systems to transport cash from the store to the office, and in pharmacies, drugs are delivered from storage to the store. Large pneumatic tube systems are built for hospitals in particular, as their sample and medication logistics can rely entirely on a pneumatic tube system.

For a hospital, pneumatic tube system design is critical

Janne Tolonen, HVAC Designer, has designed pneumatic tube systems since 2015. ‘Zenner had several pneumatic tube projects ongoing simultaneously, and I began working for them alongside my other tasks. Creating a pneumatic tube system was extremely interesting. It is a very specialized field, and you need to be able to grasp large systems and take into account the various demands of the different parts in the system.’

Janne Tolonen, HVAC Designer, has designed pneumatic tube systems since 2015. ‘Zenner had several pneumatic tube projects ongoing simultaneously, and I began working for them alongside my other tasks. Creating a pneumatic tube system was extremely interesting. It is a very specialized field, and you need to be able to grasp large systems and take into account the various demands of the different parts in the system.’

Janne Tolonen will work on the pneumatic tube system now designed for OYS. Once all plans have been implemented, the system will be very extensive, even by international standards.

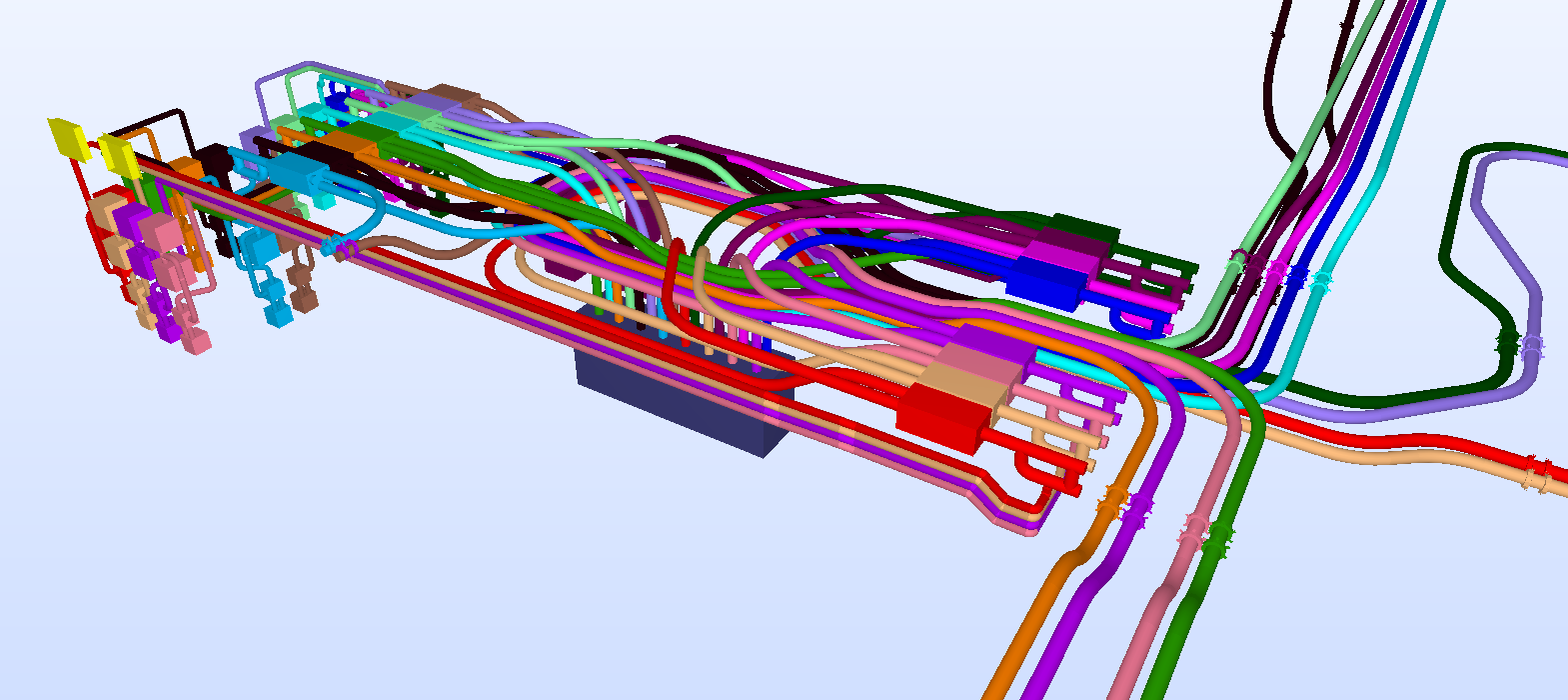

The hospital is very large, and great distances will be a challenge. Moreover, the load to the system must be planned so that deliveries from point A to B will be fast – bottlenecks are unacceptable. Building technology in general is another challenge, and information models are created together with the other designers to ensure technological compatibility.

‘Pneumatic tube systems are critical to the hospital’s operations, and their reliability is key. Pneumatic systems take samples to laboratories and deliver blood to operating theatres, for example. There is no room for delays’, explains Tolonen.

He says that as we are building a system that must be as efficient as possible, interviews conducted with future users of the system have played an important role. ‘The wishes and practices of different health care districts vary, and have a great impact on the system’s design. Moreover, new technology makes new solutions possible. Integration with other hospital equipment, such as drug dose dispensing for example, are major issues to be considered in system design.

Tolonen is appreciative of the opportunity to participate in such a large and lengthy project. ‘The project itself has been very interesting. It has also been great to learn how large projects and cooperation within them work.’